Yoogali Engineering 50th AnniversaryAdvertising Feature

Family legacy started by pioneer and still carried on by bloodAdvertising Feature

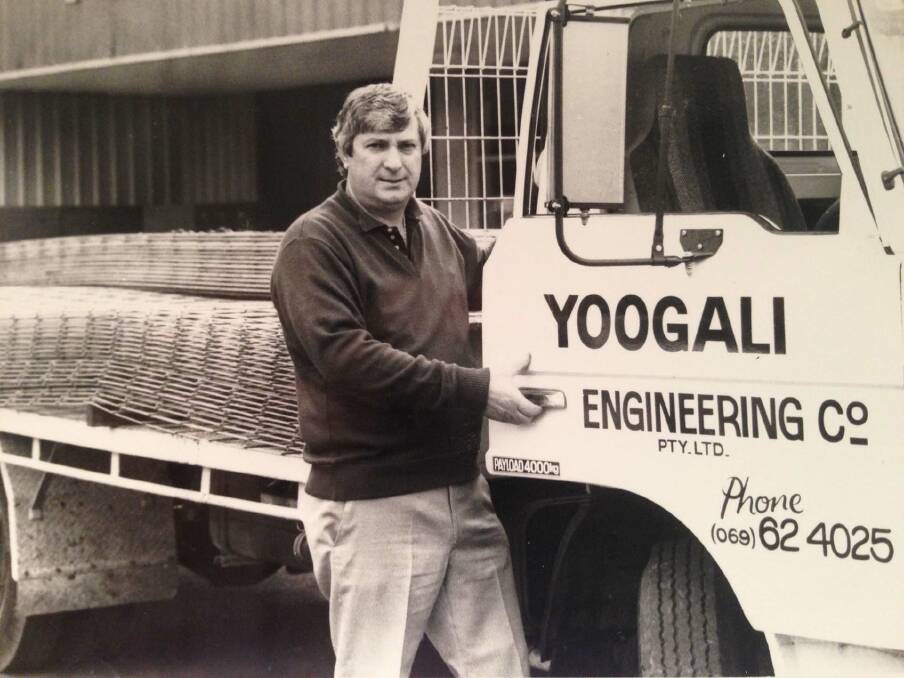

As Yoogali Engineering celebrates 50 years, they also celebrate the man vital to forging the business's sterling reputation for innovation and honesty.

Giuliano Lanza started Yoogali Engineering with two other partners, Mario Codemo and Gildo Poli, in a small shed on Bilbul Road on November 1,1973.

He was born in the small town of Ramon di Loria, in the Treviso region of Italy, and immigrated to Australia in 1965.

Following in the footsteps of his brother, Lino, he settled in Griffith.

He married his wife Regina in May 1967, the pair had four children: Monica, Zep, Marco and Chris.

During the next few years, Giuliano and his two business partners worked the long and hard hours tirelessly, and business was good.

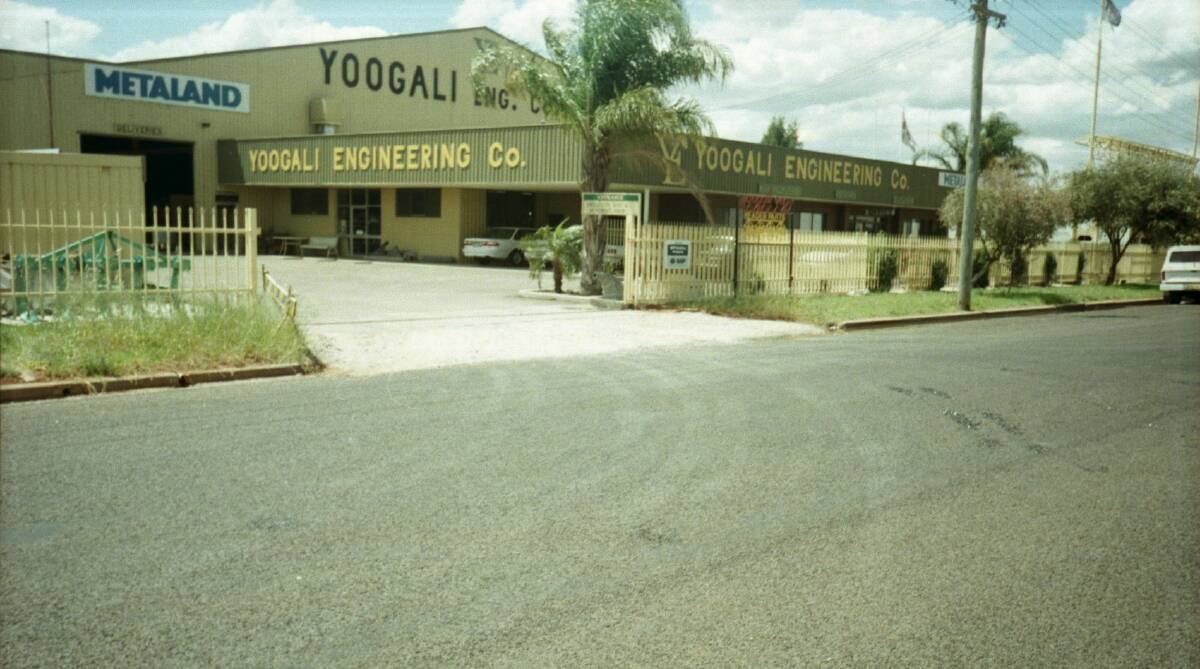

In 1976, the business moved to Collier Street and in June 1980 they moved to Whybrow Street, where the premises can be found today.

In 1984, the business bought its first crane. One of the highlights for Giuliano came in 1991 when he used that crane to lift the Firefly - affectionally and colloquially known as the 'plane on a stick' - into position in the carpark of the Griffith Visitor Information Centre.

If a farmer wanted it pruned picked or packed, Giuliano and the boys would invent a machine to do it.

- Lanza family

In the 90s, Giuliano bought out his two partners to become the sole director. Over the years, he employed scores of people and trained dozens of apprentices in Griffith.

Giuliano had a passion for his work and that passion lead him to make invaluable contributions to farmers and their agricultural enterprises in the region.

His son Marco described his father in just two words: "work and family. That's what he lived for".

While family and work came first, Giuliano was also a community man, always helping out wherever he could, doing whatever was needed.

In the late 70s and early 80s, he served as a director of the Yoogali Club and the Yoogali Soccer Club.

Up until 2012, a year before his accidental death aged 68, he was active in the community.

He was instrumental in the restoration of the Rotary wheel and restoration of the cross in St Mary's church at Yoogali.

Throughout the entire time, he was using his innovative mind to stay ahead of the times as a business man, with the industrialisation of farming progressing rapidly.

In the late 70s and early 80s, he invented specific machinery to help streamline farmers' workflow and save man-hours.

Many of his inventions are still used today and almost all of them were works of art, with his family calling him the "modern-day Da Vinci".

"If a farmer wanted it pruned picked or packed, Giuliano and the boys would invent a machine to do it," they said.

In the 90s, he started 'Header & Ag Parts Australia', a business which produces replacement parts for headers and services farmers right across Australia.

Giuliano's three sons apprenticed with him in the business: Marco in 1986, Zep in 1989 and Chris in 1997.

"A lot of my memories from the early days of working with dad, was the constant arguments over how it should be done," Zep said.

"It would make a perfect reality TV show if filmed today."

In 2005, the business changed hands with Marco and Chris Lanza taking the reins. They ensure Yoogali Engineering continues to thrive in honour of their father's legacy.

"He was an honest man who loved people," Chris said.

"He treated everyone fairly, and he always said, 'if you say you're going to do something, then you go ahead and do it'. They are the values that the business carries on today."

Proudly celebrating a half century of engineering successAdvertising Feature

It snuck up on them quickly, but there's no mistaking the pride the Yoogali Engineering team has knowing 50 years of their work contributed to making the Murrumbidgee Irrigation Area into what it is today.

The family-run business ticked over the five decade mark on November 1, and directors Chris and Marco Lanza couldn't be more chuffed.

The duo have continued the legacy started by their father Giuliano Lanza in 1973.

"There's a real sense of satisfaction in driving around and seeing all the work you and your family had a hand in," Chris said.

"There's probably not much in town that we haven't been involved with in some way."

Marco agreed, adding that without the support of the wonderful communities, the business wouldn't be the success it was today.

There's a real sense of satisfaction in driving around and seeing all the work you and your family had a hand in. There's probably not much in town that we haven't been involved with in some way.

- Chris Lanza

"Over the years it hasn't always been easy, but thanks to our committed staff and loyal customers it has been enjoyable," Marco said.

Since the beginnings of Yoogali Engineering with Giuliano and his two partners, there are now 25 staff employed across a broad range of trades and professions including welding, design, administration and sales.

Yoogali Engineering specialises in manufacturing and erecting structural steel work for building projects.

They can turn their hands to anything from residential homes and small rural sheds all the way through to large-scale developments for commercial, industrial, health, education, and hospitality industries.

Their metal fabrication workshop features some of the best modern machinery available, and plays host to a retail department proudly stocking an immense range of specialty steel.

"One of the biggest changes I've seen across my time would be the changes in technology," Chris said.

"It was instilled in us pretty strongly that to succeed, we had to be on top of the tech game."

And as such, their workshop has state-of-the-art, computer numerically controlled (CNC) machinery.

The brothers grew up watching and following their father run the business, and their sense of innovation and engineering creativity stems directly from Giuliano, who pioneered some of the great farming equipment still used today.

"He revolutionised a lot of the farming enterprises here in town - he built the first orange graders, carrot graders and onion harvesters - things that had never been done before," Chris said.

"It was something I'd always looked up to."

Marco and Chris have 30 years and 20 years respectively of official experience in fabrication, sheet metal work and welding. However they've been in the wings practically since birth.

"It has its challenges, and me and my brother butt heads from time to time but at the end of the day, we are both working towards the same thing with the same goals in mind, and that makes a difference."

Marco began working alongside his father in the late 1980s, eventually purchasing the family business with Chris in 2005.

As workshop and site manager, he is well known for his attention to detail and commitment to providing quality workmanship.

Chris, who excels in design and machine operation, takes on the project and office management responsibilities.

He has honed his broad skill set and continues to develop his project management skills, ensuring each customer's project is completed on time and on budget.

Making sure customers are completely satisfied with their service and workmanship is a non-negotiable.

Having worked on many of Griffith's most recognisable buildings, Chris hopes they'll be around for another 50 years.

"We hope that we will continue to grow and keep ticking away doing what we're doing," Chris said.

"We'll always make sure that we give good customer service, and continue building that rapport with people."

Five decades of engineering excellence leading to todayAdvertising Feature

Yoogali Engineering have been involved in numerous projects which have helped define and shape the very fabric of Griffith and the Riverina's infrastructural landscape.

With 50 years of works under their belt, some of the highlights for co-director Chris Lanza include the Hanwood Bridge and St Vincent's Private Hospital.

"Whenever you go to gatherings with people and know you've been involved with the buildings, like a lot of the clubs around town, its a great feeling," he said.

"Knowing we assisted in the private hospital build - that's incredibly rewarding."

Commercial

Organising commercial projects from start to finish, the team liase with local councils and consultants to make the process smooth.

Notable commercial projects include the manufacture and installation of the 20-metre walkway bridge in Hanwood for Griffith City Council, finished in 2020.

In 2023, they finished a project for Riverina Water Engineering/Yenda Producers, which saw them complete the architectural design, fabrication, and installation of structural steel works for a workshop, an office building and storage shed.

Education & health

Their work in the education sector hinges on stringent WHS policies, particularly when providing education centers with structural steelwork.

The team managed the fabrication, surface treatment and erection of structural steel for both the Hillston Trade Training Center in 2010 and St Francis De Sales College in 2016.

Procedural efficiency extends to health projects. They managed the workshop detail, fabrication, surface treatment, and erection of structural steel for the new Renal Unit at the Griffith Base Hospital in 2018.

Proudly, they also did the same for St Vincent's Private Community Hospital in Griffith in 2015.

Hospitality

If you head into any recreational centre in town, chances are Yoogali Engineering have left their mark there, too.

They have and continue to take on a range of projects such as renovations and new facilities for local clubs and bars, undertaking renovations to Griffith's Leagues Club and Exies Club, to name a few.

Ag & residential

But it's not just commercial and large projects - they have the residential sector down pat as well. Yoogali Engineering provide full design, fabrication, and erection of steelwork for homes, pool shelters and residential sheds.

With the business firmly grounded in the agricultural sphere of the MIA and wider region, you can be sure that if its needed on the farm, they can built it.

They've built farm machinery sheds, storage sheds, workshops, and other rural engineering projects. Add in almond, bale, rice, grain and other storage sheds, cotton gin sheds, a fertiliser shed and warehouse buildings.

The team also manufacture and install a range of conveyors, storage bins, support structures and drying tunnels for food processing projects.

Design & tech

Their in-house design team can also take projects from idea to reality by preparing council designs right through to workshop detailing, delivering executed drawings on completion of the project.

Yoogali Engineering continues to invest in the latest software and constantly keeps up-to-date with changes to relevant government legislation and the Building Code of Australia, giving customers confidence their projects are compliant.